22nd October 2025

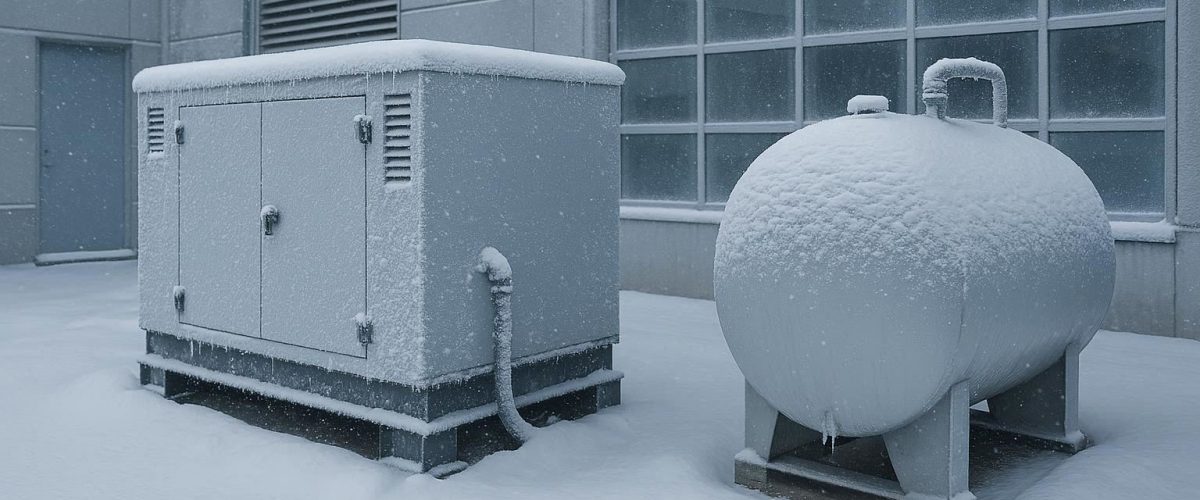

Winter poses serious challenges for diesel storage. Cold temperatures can cause diesel waxing, also known as fuel gelling, where paraffin crystals form in the fuel. This thickens diesel, blocks filters, and can prevent engines from starting. Microbial growth and water accumulation also become more prolific. Regular fuel polishing is essential to keep diesel clean, fluid, and reliable during harsh winter months.

Why Winter Fuel Maintenance Matters

Why Winter Fuel Maintenance Matters

In cold conditions, diesel is prone to:

- Diesel Waxing / Fuel Gelling: Cold causes paraffin crystals to form, thickening the fuel and obstructing filters.

- Microbial Growth: Bacteria and fungi thrive at the water-fuel interface, producing sludge that clogs filters.

- Water and Sediment Accumulation: Free and emulsified water, along with particulates, settle at the tank bottom and compromise fuel quality.

WASP PFS Fuel Polishing Systems: Winter-Ready Solutions

WASP PFS Fuel Polishing Systems: Winter-Ready Solutions

WASP Power & Filtration Solutions provides advanced fuel polishing systems to address these winter-specific issues:

- Multi-Stage Filtration: Removes particulates, microbes, free water, and emulsified water.

- Prevents Waxing/Gelling: Ensures diesel remains fluid and engine-ready.

- Versatility: Flow rates suitable for all applications.

- Smart Monitoring: Interactive colour touch screens track fuel quality in real-time.

The Benefits of WASP Fuel Polishing:

Reliable Winter Operations – keeps diesel flowing and helps prevent waxing/gelling.

Extend Equipment Life – protect injectors, pumps, and filters from damage.

Save Money – avoid costly fuel replacement and expensive repairs.

Stay Compliant – meet strict emissions standards with cleaner-burning diesel.

Be Prepared – ensure your generator starts first time, every time.

FUEL POLISHING | W-PFS PREMIUM RANGE | WB CLASSIC RANGE | W-HL HIGH LIFT RANGE