9th December 2025

Protecting the quality of stored fuel is essential for safeguarding equipment, reducing downtime, and maintaining long-term operational performance. A well-specified fuel polishing system plays a central role in achieving this, but with multiple variables to weigh up, it’s important to get the details right from the very beginning.

Whether you’re maintaining back-up power systems, supporting critical infrastructure, or managing multiple storage tanks across a site, the following considerations will help you define the most effective and efficient fuel polishing solution.

1. Location & Installation

Understanding the installation environment is the first step in determining the right system.

Key questions to ask:

Where will the fuel polisher be installed in relation to the tank(s)?

Distance, pipework routing, and accessibility all influence the final specification.

Where are the suction and return points located?

This affects pump sizing, hose lengths, and overall system design.

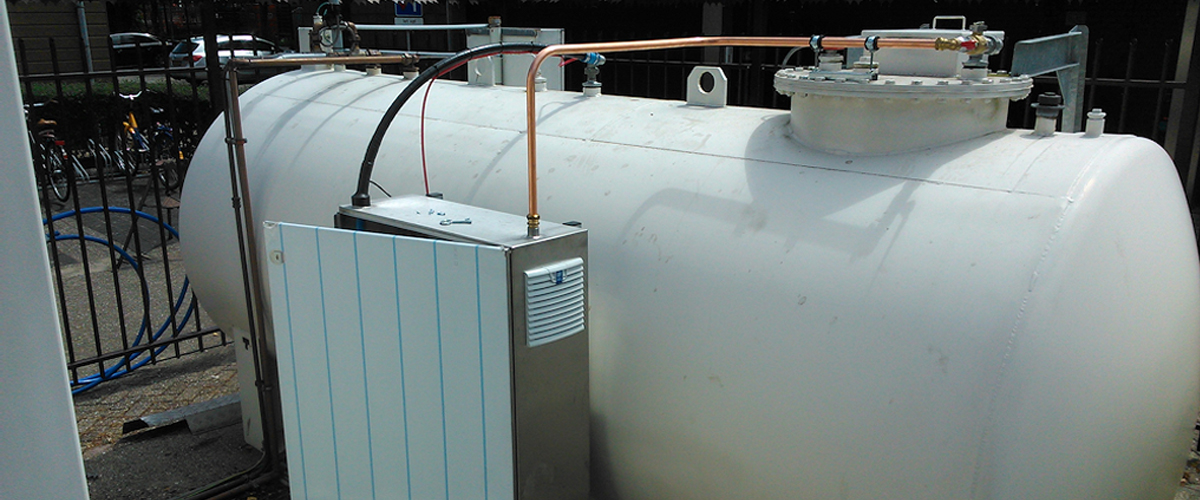

Is the installation indoors, outdoors, or in containment?

Outdoor and mobile units may require weatherproofing, protective enclosures, or bunded housings.

2. Tank Requirements

Tank characteristics directly determine the capacity and performance requirements of your fuel polishing system.

Consider:

Tank dimensions, capacity, and volume.

Larger tanks or multiple tanks often require higher flow rates or extended duty cycles.

Fuel turnover rate.

Long-term stored fuel with low turnover is more prone to contamination and microbial growth, increasing the need for robust and regular polishing.

High-usage sites may require systems capable of fast, frequent circulation.

3. Filtration & System Design

Filtration is the heart of any fuel polishing system, so choosing the right configuration is essential.

Think about:

Single or multi-stage filtration.

Multi-stage systems allow progressive removal of particulates and water, improving efficiency and filter life.

Servicing more than one tank.

A centralised system may be more cost-effective and space-efficient.

Combined fuel transfer and polishing.

Integrated solutions streamline operations and reduce the need for additional equipment

4. Power & Connectivity

Your site’s power availability and monitoring needs will influence equipment choice.

Key considerations:

Single-phase or three-phase electrical supply?

Pump size and power requirements generally dictate this.

Do you require cloud integration?

Remote monitoring, alerting, and data insight can significantly enhance maintenance planning and compliance.

5. Additional Features to Consider

To maximise system performance and ease of maintenance, you may want to include other features such as:

Sight glass: for quick, visual confirmation of fuel quality

Magnetic inserts: to capture ferrous debris before it hits the filters

Flow meter: to verify performance or record circulation rates

Particulate counter: for real-time cleanliness monitoring and compliance reporting

Getting the Specification Right

Choosing the right fuel polishing system isn’t just about filtration, it’s about understanding your environment, your fuel usage patterns and the operational needs of your site. By clarifying these considerations early on, you ensure your fuel remains clean, compliant, and ready to perform whenever you need it.

FUEL POLISHING | W-PFS PREMIUM RANGE | WB CLASSIC RANGE | W-HL HIGH LIFT RANGE