21st August 2025

Diesel standby generators are the last line of defence for data centres. Yet their reliability ultimately depends on fuel quality – a factor that quietly degrades over time through water ingress, particulate contamination, and microbial growth (“diesel bug”). Left unchecked, these contaminants clog filters, corrode tanks and injectors, and cause generators to stumble right when they’re needed most. High-performance, fully automated WASP Fuel Polishing Systems address this risk head-on by continuously maintaining fuel to a clean, dry, and stable condition without manual intervention.

Diesel standby generators are the last line of defence for data centres. Yet their reliability ultimately depends on fuel quality – a factor that quietly degrades over time through water ingress, particulate contamination, and microbial growth (“diesel bug”). Left unchecked, these contaminants clog filters, corrode tanks and injectors, and cause generators to stumble right when they’re needed most. High-performance, fully automated WASP Fuel Polishing Systems address this risk head-on by continuously maintaining fuel to a clean, dry, and stable condition without manual intervention.

Clean fuel doesn’t stay clean!

Clean fuel doesn’t stay clean!

Even in sealed tanks, fuel ages. Temperature cycles cause condensation; tank returns re-suspend sludge; and biodiesel blends are more hygroscopic and nutrient-rich, accelerating microbial growth. Periodic manual sampling and filter changes can’t keep pace with these dynamics, especially across distributed tank farms and day tanks typical of large facilities. A single failure can put contractual SLAs, reputations, and safety at risk.

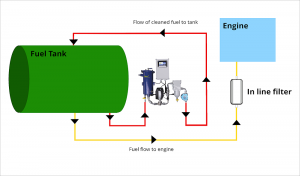

WASP Fuel Polishing Systems are designed to run independently of generator operation, recirculating stored diesel through multi-stage separation and filtration. They remove free and emulsified water, strip particulates that abrade fuel system components, and disrupt microbial colonies by eliminating the water layer they need to thrive. Integrated controls, sensors, and alarms provide continuous condition monitoring and tie into the building management system (BMS), enabling proactive maintenance rather than reactive firefighting.

Key benefits for data centre operators:

Key benefits for data centre operators:

Reliable generator performance – Clean, dry fuel ensures first-time starts and stable load acceptance.

24/7 Automated protection – Continuous polishing maintains fuel quality without manual intervention.

Effective water removal – Prevents microbial growth, corrosion, and sludge build-up.

Extended equipment life & lower maintenance costs – Protects injectors, pumps, and filters.

Real-time visibility & proactive action – Integrated sensors and alarms support timely interventions.

Compliance & audit support – Logged polishing data helps meet internal and external standards.

Compliance & audit support – Logged polishing data helps meet internal and external standards.

Scalable design – Suitable for individual tanks or large multi-generator campuses.

Reduced environmental impact – Minimises fuel waste, disposal, and emissions.

Implementation best practices

Position polishing loops to recirculate the entire tank volume on a routine schedule, not just the top layer. Draw from low points where water and sludge accumulate, and return flow to promote mixing. Integrate differential pressure, water-in-fuel, and runtime telemetry with the BMS for central visibility. Finally, pair polishing with periodic tank inspections and good housekeeping (breather filters, moisture control, and disciplined fuel procurement) for a complete reliability strategy.

FUEL POLISHING | W-PFS PREMIUM RANGE | WB CLASSIC RANGE | W-HL HIGH LIFT RANGE