W-701 WASP Primary Fuel Filter

|

The problems that can occur due to water and sediment in fuel are well known and WASP Filters offer a wide choice of options to cover most requirements. All metal bowl units meet and exceed the requirements of ISO 10088 Annex B. Flow rates range from 1 - 20,000 liters per hour and port sizes are from 1/4'' BSP to 2'' BSP. A DN 50 flanged version is available on the 2'' ported model. All models have a maximum working pressure of 4 bar. These WASP strainers are fitted with a well constructed 'washable' stainless steel element that will give many years of effective service. Micron ratings available are 60, 100 and 300 with 400 micron offered on the 2'' models. Pre-cleaning liquids by passing it through a washable strainer will assist in reducing costs down stream. The only consumable item in the WASP Liquid Strainers is a seal kit.

|

View the embedded image gallery online at:

https://wasp-pfs.com/products/fuel-filters/w-701#sigProId81a5d676db |

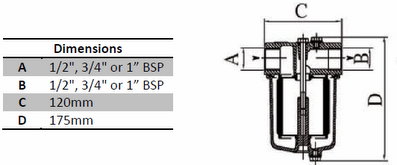

- Up to 20,000 litres per hour flow rate

- 1/2'' to 1'' BSP connections

- Inexpensive solution

- Choice of separators, paper elements or long life stainless steel

- LM6 grade aluminium filter heads with reversible stainless steel bracket & bolts

- Powder coated aluminium filter heads for corrosion prevention & long service life

- 60 & 300 micron stainless steel washable elements

- How does it work?

-

1. Separation:

The incoming flow of fuel oil changes velocity and direction, reducing the possibility of further reduction of any water droplets present through impact.2. Coalescence:

This takes place on and just below the flow dispersion member allowing the separated water to descend to the bottom of the filter bowl.3. Filtration:

The fuel finally passes through the stainless steel filter element. This removes all particulate above 100 micron still suspended in the fuel after the separation process.

| W-7010x range | Filtration (micron) | Ports | Bowl |

| W-70107/006 | 60mic stainless steel | 1/2” Ports | Metal |

| W-70107/01 | 100mic stainless steel | 1/2” Ports | Metal |

| W-70107/03 | 300mic galvanised steel | 1/2” Ports | Metal |

| W-70104/006 | 60mic stainless steel | 3/4” Ports | Metal |

| W-70104/01 | 100mic stainless steel | 3/4” Ports | Metal |

| W-70104/03 | 300mic galvanised steel | 3/4” Ports | Metal |

| W-70101/006 | 60mic stainless steel | 1” Ports | Metal |

| W-70101/01 | 100mic stainless steel | 1” Ports | Metal |

| W-70101/03 | 300mic galvanised steel | 1” Ports | Metal |

For more technical information, please see the Technical Details tab.

| W-7010x range | Filtration (micron) |

| W-FS13 | W-7010x range mounting bracket |

| W-60100/006 | Replacement 60 mic pleated stainless steel element |

| W-60100/01 | Replacement 100 mic pleated stainless steel element |

| W-60100/03 | Replacement 300 mic pleated galvanised steel element |

| W-3207 | Gasket kit |

| W-3207V | Viton gasket kit |

Model 70107 can be fitted with a magnetic column to remove ferrous particles.

| MODEL | FLOW RATE (litres / hour) | ELEMENT | PORT SIZE | DIMENSIONS (mm) |

|

W70107/006

|

1000 - 2000

|

60 mic ss

|

½" BSP

|

120 x 181

|

|

W70107/01

|

1000 - 2000

|

100 mic ss

|

½" BSP

|

120 x 181

|

|

W70107/03

|

1000 - 2000

|

300 mic gs

|

½" BSP

|

120 x 181

|

|

W70101/006

|

2000 - 3000

|

60 mic ss

|

1" BSP

|

120 x 181

|

|

W70101/01

|

2000 - 3000

|

l00 mic ss

|

1" BSP

|

120 x 181

|

|

W70101/03

|

2000 - 3000

|

300 mic gs

|

1" BSP

|

120 x 181

|

Notes:

Flow rates are approximate

ss = stainless steel gs = galvanised steel F = flanged connections

Aluminium filter body and cover- maximum working pressure 4 bar - maximum operating temperature 90°C

Maximum operating pressure 2bar

Max operating temp (metal bowl) 90 deg C

Compatible with diesel and heavy oil

Installation

The flow direction is indicated by arrows and must be observed. The filters can be installed in any position, however, we recommend that filter units are mounted vertically with the cover uppermost. This will assist the separation and collection of any water and particulate into the bottom of the housing ready for drain off (water separation of diesel fuel will only take place at lower flow rates).

Servicing

Due to the simple and effective construction very little maintenance is required other than draining off any impurities, and the periodic removal of the washable element for cleaning.

Cleaning the filter is carried out by unscrewing the central bolt and then unscrewing the bowl. Carefully wash the filtering element with clean diesel, gas-oil or gasoline. Remount the unit and check that the seals are integral and well placed. Paper elements should be replaced as they cannot be reused (see above spares). Water can be drained by opening the bleed screw on the lid and then the water drain at the bottom of the bowl.

Fuel Filters Fuel Polishing Gallery Fuel Contaminations Fuel Additives