W-PFS-120 Premium Fuel Cleaning System

120 litres per minute fuel polishing system, cleaning fuel to 2 micron, removing both free and emulsified water, bacteria and particulate.

This frame mounted 220v AC unit can be custom built to your specifications and offers medium to high flow fuel cleaning with manual, automatic and BMS control. Complete monitoring is at your finger tips with our user friendly colour touch screen control system. The PFS range can be custom built to your specifications and we have a wide range of add-on options to meet all your needs.

SUITABLE FOR

SUITABLE FOR

Tank sizes 80,000 to 200,000 litres, cleaning 120 litres per minute. Available in 220vAC.

TOUCH SCREEN CONTROL

TOUCH SCREEN CONTROL

Easy to use, manual and auto set up, BMS, reporting and trending, export data, Ethernet desktop sharing and much more.

CLEAN TO 2 MICRON

CLEAN TO 2 MICRON

Including removal of emulsified and free water, bacteria, dirt, and particulate.

FUEL PROTECTION

FUEL PROTECTION

For data centres, generators, hospitals, marine, agricultural tanks, banking, government, embassies..

-

Multi-tank cleaning

Multi-tank cleaning

Multi-tank cleaning

Multi-tank cleaning

-

Best quality fittings

Best quality fittings

Best quality fittings

Best quality fittings

-

Colour touchscreen included

Colour touchscreen included

Colour touchscreen included

Colour touchscreen included

-

Add-on: Heater /cooler option

Add-on: Heater /cooler option

Add-on: Heater /cooler option

Add-on: Heater /cooler option

-

Add-on: Auto biocide dosing

Add-on: Auto biocide dosing

Add-on: Auto biocide dosing

Add-on: Auto biocide dosing

-

Add-on: Drip Tray

Add-on: Drip Tray

Add-on: Drip Tray

Add-on: Drip Tray

-

Add-on: Enclosure

Add-on: Enclosure

Add-on: Enclosure

Add-on: Enclosure

-

Add-on: Modbus

Add-on: Modbus

Add-on: Modbus

Add-on: Modbus

-

Add-on:Trolley Mounted

Add-on:Trolley Mounted

Add-on:Trolley Mounted

Add-on:Trolley Mounted

-

Add-on: Towing Unit

Add-on: Towing Unit

Add-on: Towing Unit

Add-on: Towing Unit

-

Fuel Polishing Results

Fuel Polishing Results

Fuel Polishing Results

Fuel Polishing Results

-

Injector damage

Injector damage

Injector damage

Injector damage

-

Water contamination

Water contamination

Water contamination

Water contamination

-

Fuel Tank Contamination

Fuel Tank Contamination

Fuel Tank Contamination

Fuel Tank Contamination

-

Bacterial infection

Bacterial infection

Bacterial infection

Bacterial infection

-

W-PFS-120 System

W-PFS-120 System

W-PFS-120 System

W-PFS-120 System

https://wasp-pfs.com/products/fuel-polishing-systems/w-pfs/w-pfs-120#sigProIdef84a1fd33

- Advanced, high speed 220v AC system, providing full control system and monitoring

- Manual, Automatic (timer) and BMS control system

- Fuel conditioning stage for anti-bacterial action, eliminates the build-up of algae and water in your tanks

- Patented centrifugal removal process

- Recirculation or transfer action

- Service filter alarm

- Water in fuel alarm

- Differential alarm

- 99.9 % free water removal in a single pass

- 99 % emulsified water removal in a single pass

- 2 micron final polish/fuel cleaning

- Add-on options available

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|||

|

Frame with or |

|||

|

W-PFS-120 120 lit/min Power Option |

220v 50hz 1ph AC |

||

Need help selecting the right system for your requirements? Use our new Product Selector.

For more technical information, please see the Technical Details tab.

| Model | W-PFS-120 |

| Max flow rate | 120 lit/min max fuel flow rate** |

| Recommended tank size | Up to 200,000 litres |

| Power options |

220v 50hz 1ph AC |

| Finish options |

Frame with or without enclosure |

| Particulate removal to | 2 Micron |

| Control unit | Touchscreen |

| BMS outputs | 6 |

| BMS inputs | 2 |

| Fuse | 5a |

| Typical current | 5a |

| Suction capability | 1.5m vertical lift, over 5m with non-return valve fitted and when primed |

| Port sizes | 2" BSP |

| Pump body | Stainless Steel |

| Pump type | Stainless Steel |

| Shaft | Stainless steel |

| Seal | Flouoroelastomer |

| Dimensions * |

1000x1500x1800mm |

| Weight * |

245KG |

* Measurements above are for the wall mounted version. Please enquire for weights and dimensions for alternative finishes.

**Flow rates quoted assume the ideal conditions, a large positive head, no left, wide pipe work, etc. Narrow pipes, tight bends, elbows, lifts and other such external factors can and will impact on the maximum flow achieved by the system.

-

Ensure the system is securely fastened to a wall or other suitable solid structure.

-

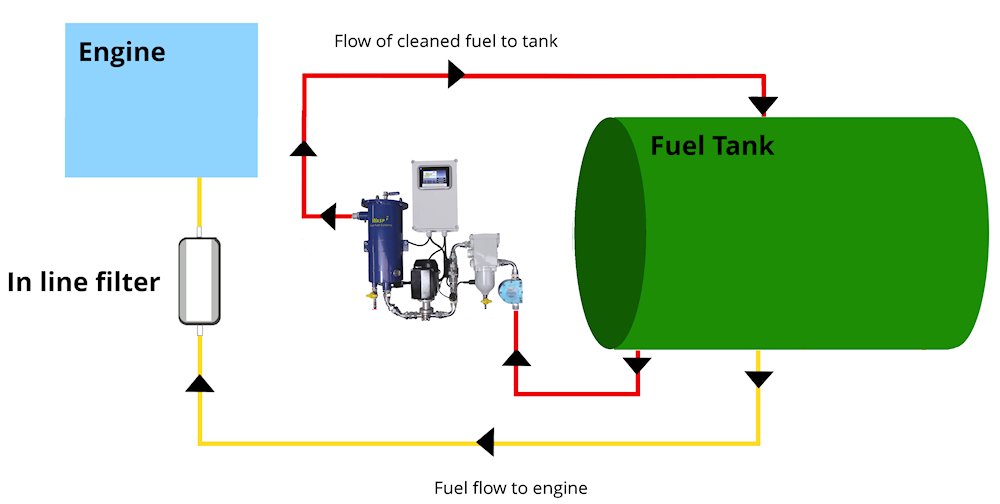

The unit should have unique pipe work from any existing fuel driven equipment. The input to the WASP system should feed from the bottom of the fuel tank (via a ball valve and a foot valve or non return valve)

-

The system should pick-up fuel from the lowest point of the tank at one end, (below the level of the fuel feed to your engine) and ideally return it to the highest point at the opposite end.

- The output should return to the tank at the top, opposite end to the input ideally.

- The unit can be controlled via BMS, however it is capable of self operation and monitoring.

- System must be primed before use and operation. It must also be primed after servicing; although with the aforementioned foot or non return valve installed, priming should only need to be done once after installation.

- With power applied, please ensure the system’s time and date have been correctly set.

- We recommend an internal pipe diameter of 3/4” for the 010 model and 1” for the others; however larger diameters will assist the unit as this reduces the frictional losses. Small diameters, long pipe runs or many bends in the pipe work will cause high frictional losses and cause the system to run slower than its maximum speed, or in extreme cases cause it to stop. Likewise high fuel lifts or fuel heads will also cause the unit to run slower.

-

In any typical fuel tank, the pipe feeding fuel to the engine is not at the bottom, however to successfully clean fuel, the pickup pipe going to the WB unit should be right at the bottom of the tank, below the engine feed.

- Full W-PFS Range of products

- W-PFS-008

- W-PFS-010

- W-PFS-014

- W-PFS-026

- W-PFS-040

- W-PFS-060

- W-PFS-240

- W-PFS Range Brochure

- WB Fuel Cleaning Range

- Compare WB and W-PFS

- Use our helpful product selector

- New to fuel polishing?

- How does it work?

- Spare Parts Page

- Product Support

- Download the Protecting your data PDF

- Fuel polishing Add-ons

Try our helpful new PRODUCT SELECTOR to select the model for your needs.