Use Product Selector

Fuel Polishing Product Selector

Whether you are new to fuel polishing or experienced in the field, our NEW interactive product selector is a quick and easy tool to choose the ideal system for you.

See Range

Product Spares

Supplying our existing customers with a wide range of spares including filter elements, seals and conditioners. We provide a range of delivery options including worldwide shipping and rapid UK services, ensuring minimal, if any disruption to your fuel cleaning.

Get help

Customer Support

Offering product training, installation, telephone support, on site assistance, CPD training and fuel maintenance courses. We have experts in fuel filtration, fuel stability, hydraulics, design, electronics, fieldbus, and more.

FOCUS ON DISTRIBUTORS

-

WORLDWIDE COVERAGE

Distributors covering Europe, N. America, Asia, , Australia, Middle East and more. -

ISO9001:2015

WASP PFS Ltd are proud to be ISO Approved -

UK BUILT QUALITY SYSTEMS

Systems are designed and built in the UK

Why Choose WASP ?

Complete Product Range

WASP provides complete critical power solutions with our extensive range of products and services. Quality fuel polishing systems, switchgear, sidestream filtration, fuel additives, pumps, filters, oil change systems, fuel conditioners, and professional fuel testing services.

Built to your specifications

Do you need something specific? Our in-house team of experts can discuss your requirements and provide the ultimate solution using the latest technology.

Developing and testing new filtration technologies

At WASP we are passionate about Fuel Polishing. We constantly strive to develop our range of products. By testing new mechanical, electrical and filtering technologies we are always at the cutting edge of Fuel Polishing.

Premium Quality

We are a manufacturer who takes pride in the quality of our products; which is why we are ISO9001 accredited. Solutions are built to a high standard with only the best quality pumps, filters, fittings, and electrical components to provide durability and powerful results.

Worldwide Supplier Network

With a large network of WASP offices and international suppliers, there is always an experienced WASP representative near to you.

Supporting you with expert knowledge

With over 50 years of combined experience, we provide you with expert knowledge and experience from the project proposal stage and design, to supply, installation, commissioning and product support.

Switchgear, Fuel Polishing, Fuel Cleaning Systems, Sidestream Filtration, and Services.

-

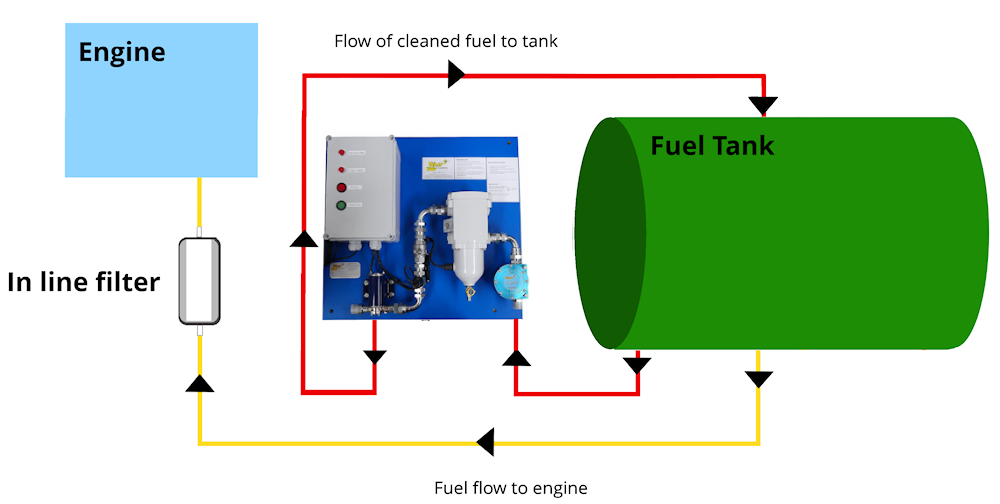

The WB range of products is typically wall mountable and should be installed close to the fuel tank it is cleaning.

In any typical fuel tank, the pipe feeding fuel to the engine is not at the bottom, however to successfully clean fuel, the pickup pipe going to the WB unit should be right at the bottom of the tank, below the engine feed.

The return pipe from the WB unit should ideally be at the top of the tank at the opposite end to the pick up; if this is not possible the top of the tank at the same end is acceptable.

Apart from that, the list below highlights our recommendations.

- A fused spur is required to power the system (24v DC or 220v 50hz 1ph AC).

- Only two pipes are required (input/pickup and output/return)

- We recommend a non return valve on the input pipe

- Alternatively we recommend a foot valve at the tank end of the input pipe

- We recommend isolating ball valves before and after the system