Use Product Selector

Fuel Polishing Product Selector

Whether you are new to fuel polishing or experienced in the field, our NEW interactive product selector is a quick and easy tool to choose the ideal system for you.

See Range

Product Spares

Supplying our existing customers with a wide range of spares including filter elements, seals and conditioners. We provide a range of delivery options including worldwide shipping and rapid UK services, ensuring minimal, if any disruption to your fuel cleaning.

Get help

Customer Support

Offering product training, installation, telephone support, on site assistance, CPD training and fuel maintenance courses. We have experts in fuel filtration, fuel stability, hydraulics, design, electronics, fieldbus, and more.

FOCUS ON DISTRIBUTORS

-

WORLDWIDE COVERAGE

Distributors covering Europe, N. America, Asia, , Australia, Middle East and more. -

ISO9001:2015

WASP PFS Ltd are proud to be ISO Approved -

UK BUILT QUALITY SYSTEMS

Systems are designed and built in the UK

Why Choose WASP ?

Complete Product Range

WASP provides complete critical power solutions with our extensive range of products and services. Quality fuel polishing systems, switchgear, sidestream filtration, fuel additives, pumps, filters, oil change systems, fuel conditioners, and professional fuel testing services.

Built to your specifications

Do you need something specific? Our in-house team of experts can discuss your requirements and provide the ultimate solution using the latest technology.

Developing and testing new filtration technologies

At WASP we are passionate about Fuel Polishing. We constantly strive to develop our range of products. By testing new mechanical, electrical and filtering technologies we are always at the cutting edge of Fuel Polishing.

Premium Quality

We are a manufacturer who takes pride in the quality of our products; which is why we are ISO9001 accredited. Solutions are built to a high standard with only the best quality pumps, filters, fittings, and electrical components to provide durability and powerful results.

Worldwide Supplier Network

With a large network of WASP offices and international suppliers, there is always an experienced WASP representative near to you.

Supporting you with expert knowledge

With over 50 years of combined experience, we provide you with expert knowledge and experience from the project proposal stage and design, to supply, installation, commissioning and product support.

Switchgear, Fuel Polishing, Fuel Cleaning Systems, Sidestream Filtration, and Services.

Switching on to Fuel Polishing Systems - In Healthcare

Editorial article published in Healthcare Design and Management magazine in July 2014.

To read the article and full magazine on line, please click here. Alternatively the article has been reproduced below.

Hospitals are busy environments that have to operate around the clock. This means a constant supply of power for things like lighting and heating, but also to run the plethora of medical appliances used in every healthcare setting. In the case of a failure, hospitals use back-up generators that kick in should the general supply fail.

But, with outages thankfully rare, are hospitals doing enough to ensure their emergency systems are in good condition?

Last year in the US a series of hurricanes threw this issue into the spotlight, with hospitals finding themselves without critical power. One of the reasons for this problem is that back-up generators use fuel and that fuel has to be in tip-top condition. So, as was the case in the US, if systems have not been checked for several years, or even decades in some instances, they will not do the job they were installed to do.

In the UK hospitals are beginning to realise this and are taking measures to reduce the risk. One Birmingham hospital recently installed 10 fuel polishing systems on its back-up generators as a preventative measure.

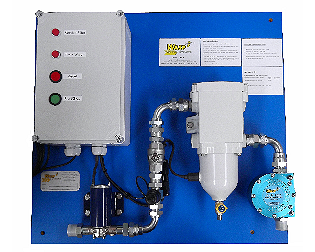

The increasingly-popular technology, supplied by WASP PFS, will maintain the quality of the stagnant or stored fuel in the back-up generator tanks, helping to prevent the generators from failing during an emergency situation.

Speaking to hdm, Geoff Ross, sales director at WASP, explained: “The hospital called us in and we recognised there was a problem and identified free water, emulsified water, microbial growth and other contaminations in the fuel within the back-up generator. The water was a threat to the generator's fuel system and could have caused damage to, or even destroyed, its injectors. Furthermore, it increased the fuels acidity levels, caused the breeding of bacteria and the formation of biomass. This blocked the fuel pipes and filters and caused the engine to lose efficiency.

Geoff Ross- WASP PFS Ltd

“During an emergency situation, these problems could have caused their generators to stall or fail completely, which would risk the lives of patients undergoing high-risk surgical procedures, or those relying on respiratory equipment in cardiac units or intensive care units. It would also risk staff wellbeing while working in rooms without any back-up lighting.”

The WASP system works by removing the ingress water and contaminations from the fuel and restoring it to optimum quality within a matter of hours.

“Recycling the fuel costs far less than disposing it and sourcing more, not just in monitory terms but also in terms of carbon emissions,” said Ross.

“Recycling the fuel costs far less than disposing it and sourcing more, not just in monitory terms but also in terms of carbon emissions,” said Ross.

“We did one hospital in Gloucester that had spent £750,000 on fuel for its back-up generators, so this is no small amount we are talking about. It makes sense to invest in something that is not very expensive, but will ensure that back-up generators do the job they were intended to do at a time when maintaining services is critical.”

Article from Healthcare Design Magazine Download New Flyer W-PFS Premium Range Case Studies FAQ